Ultraviolet Microscope

The UV Microscope is a microscope that can image in the ultraviolet region.

UV microscopes "see" beyond what a standard optical microscope can image. With special UV optics, light sources and cameras, UV microscopes image microscopic samples in the visible and the ultraviolet regions. This means that UV microscopes have features that make them superior to normal visible range microscopes:

- Some materials are invisible in normal microscopes but can be imaged with UV microscopes

- By using the shorter wavelengths of UV light, higher image resolution can be obtained than with the longer wavelengths of visible range light.

One example is in imaging protein crystals: these microscopic crystals are transparent in the visible range but can be easily seen at 280 nm due to the strong absorbance of certain amino acids.

CRAIC Technologies offers a number of solutions for the UV microscope. These custom designed microscopes capable of imaging from the deep UV all the way into the near IR. They are capable of UV microscopy in transmission, reflectance and even fluorescence.

Learn more about UV microscopes:

Cytospectrometer

The Cytospectrometer measure the UV-vsibile-NIR spectra of sub-cellular components.

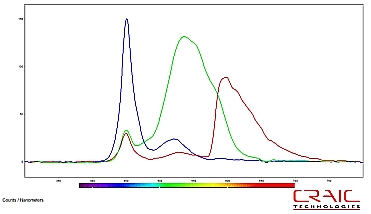

The Cytospectrometer is designed to measure UV-visible-NIR spectra of cellular components. In other words, the cytospectrophotometer is a microspectrophotometer of which there are two basic types: the fully integrated microspectrophotometer that has been built and optimized for microspectroscopy and the spectrophotometer unit designed to attach to an open photoport of a biologicalal microscope. Depending upon the configuration, both are capable of measuring the spectra of microscopic samples by transmission, absorbance, reflectance, fluorescence, emission and polarization microspectroscopy. With special software, both are capable of surface spectral mapping measurements and colorimetry as well.

A CRAIC Technologies™ microspectrophotometer is a purpose-built system that allows you to analyze UV-visible-NIR range microspectra™ non-destructively and with no sample contact. Capable of analyzing even sub-micron areas, they are also capable of high resolution digital imaging. Designed for ease-of-use, they are durable instruments designed for microscale spectroscopy.

To learn more about microspectrophotometry and microspectrophotometers, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometry

Uses of Microspectrophotometers

Fluorescence

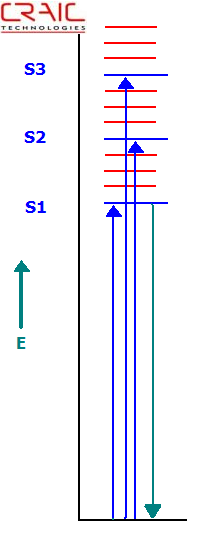

Fluorescence is the emission of a photon with the decay from the S1 excited state to the S0 ground state. Generally, fluorescent emissions occur approximately 10-9 to 10-7 seconds after excitation. Fluorescence spectrometers are designed to collect and measure the emitted photons.

The microfluorometer is a fluorescence spectrometer interfaced with a microscope. They are designed to measure fluorescence spectra of microscopic samples or microscopic areas of larger objects. There are two basic types: the fully integrated microfluorometer that has been built and optimized for fluorescence microspectroscopy and the fluorescence spectrometer unit designed to attach to an open photoport of an optical microscope. The beauty of microfluorometers is that they can also be configured to measure the transmission and reflectance spectra of microscopic sample areas in addition to fluorescence. And with special software, they are capable of colorimetry as well.

A CRAIC Technologies™ microfluorometer is a purpose-built system that allows you to analyze UV-visible-NIR range fluorescent emissions non-destructively and with no sample contact. Capable of analyzing even sub-micron areas, they are also capable of high resolution digital imaging. Designed for ease-of-use, they are durable instruments designed for microscale spectroscopy.

To learn more about microspectroscopy and microfluorometers, select one of the following links:

Fluid Inclusions

Fluorescence Microspectroscopy can be used to analyze fluid inclusions.

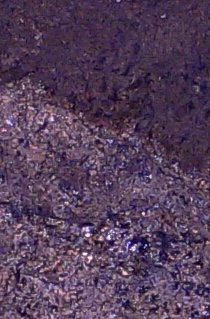

Fluid Inclusions are microscopic pockets of gas or liquids trapped within minerals. The contents of these pockets may contain information on the original physical and chemical conditions in which the source rock formed. This information can be useful for many applications including mineralogical surveys and petroleum exploration.

CRAIC Technologies offers a number of solutions for the analysis of fluid inclusions. These include purpose built systems such as the CRAIC CoalPro™ to the 508 Coal™ and 20/30 PV™ for advanced microscopic imaging and spectral analysis of petrographic samples. These systems are capable of transmission, reflectance and fluorescence microspectroscopy and imaging of even sub-micron fluid inclusions.

To learn more about the science behind fluid inclusion analysis, select one of the following links:

Uses of Microspectrophotometers

CRAIC CoalPro™ Measurement System

508 Coal™ Spectrophotometer for your Microscope

Petrography

Petrography is the detailed examination of rocks including the analysis of fluid inclusions.

Petrography is the detailed study of rocks, most commonly on the microscopic scale. Such studies can include simple imaging, measuring the luminous intensity with a microscope photometer, or the transmission, reflectance and even fluorescence spectra with a microscope spectrophotometer. Some of the most common applications are fluorescence microspectroscopy of fluid inclusion, vitrinite reflectance of coal and kerogens as well as the spectral analysis of gemstones and minerals.CRAIC Technologies offers a number of petrographic solutions. These include purpose built systems such as the CRAIC GeoImage™ Vitrinite Reflection Measurement System to the 508PV™ for advanced microscopic imaging and spectral analysis of petrographic samples.

To learn more about the science behind petrographic analysis, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometers

GeoImage™ Vitrinite Reflectance and Point Counting

508PV™ Spectroscopic Vitrinite Reflectance with your microscope