Spectral microscopy!

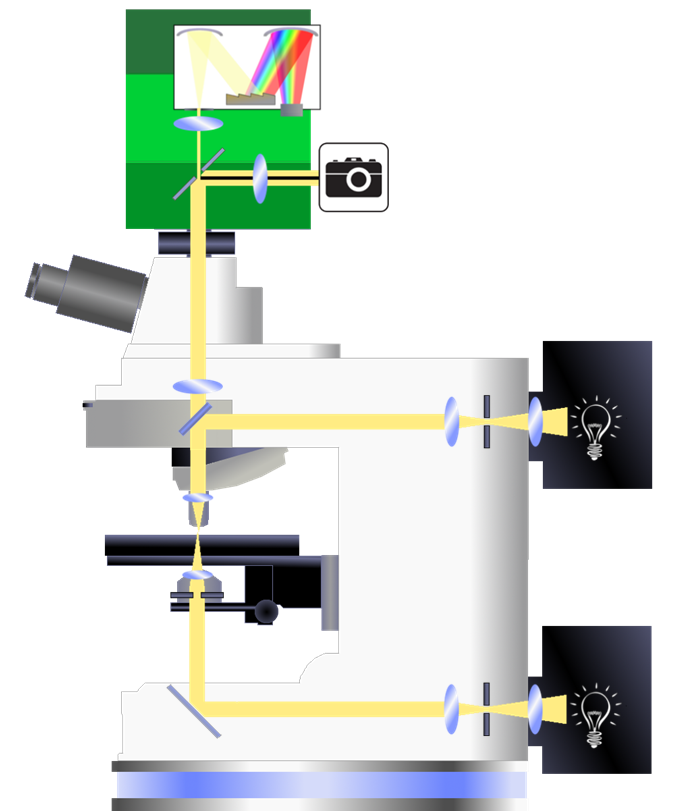

As shown in the diagram on the right, the MSP head unit can be added to the photoport of a microscope, and the spectrometer measures the light that is collected by the objective and focused onto the spectrophotometer entrance aperture. Whether this light is transmitted through the sample, reflected from the sample, or emitted by the sample, that only changes the calculations done on the light intensity measured.

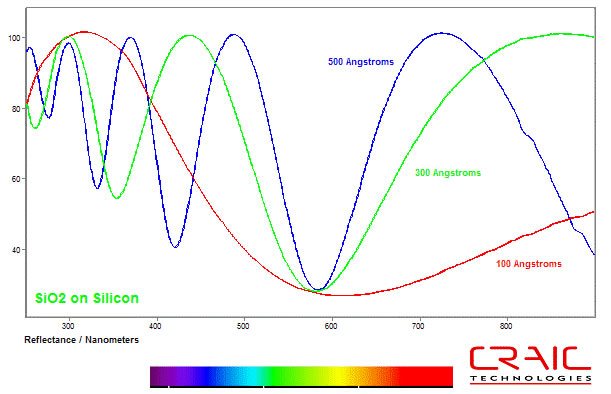

Beyond just measuring UV-VIS-NIR spectra with microscale sampling areas, spectral microscopy is also capable of microspot thin film thickness and colorimetry measurements. When combined with motorized stages, hyperspectral data cubes can even be created with various types of spectra. Because these instruments are so flexible, MSP's are used in many diverse fields of research and industry.

Spectral microscope

As shown in the diagram on the right, the MSP head unit can be added to the photoport of a microscope, and the spectrometer measures the light that is collected by the objective and focused onto the spectrophotometer entrance aperture. Whether this light is transmitted through the sample, reflected from the sample, or emitted by the sample, that only changes the calculations done on the light intensity measured.

Beyond just measuring UV-VIS-NIR spectra with microscale sampling areas, microscope spectrophotometers are also capable of microspot thin film thickness and colorimetry measurements. When combined with motorized stages, hyperspectral data cubes can even be created with various types of spectra. Because these instruments are so flexible, MSP's are used in many diverse fields of research and industry.

Colloidal Materials Research

Microspectrophotometers are used to analyze colloids and colloidal materials by imaging and spectroscopy

A colloid is a substance that is evenly dispersed on the microscopic scale throughout another substance. Colloidal substances have many different applications ranging from pharmaceuticals to Raman spectral enhancement materials. Colloids can either be naturally derived or created by such processes as high shear techniques. Due to their unique nature, they have many useful and interesting properties.

Due to the microscopic scales of colloids and colloidal solutions, microspectrophotometers are the perfect tool. Able to analyze micro-scale samples by absorbance, reflectance or even fluorescence, these tools are easy-to-use and very accurate. Their flexibility and accuracy make them very importance for analyzing everything from the optical effects of butterfly wings to protein crystals.

To learn more about microspectroscopy and colloid and colloidal research applications, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometers

Revolutionize Your Microscopy with Raman Spectroscopy!

Optical microscopes are staples in many laboratories, typically used to magnify samples for better observation. However, with the addition of a laser, a Raman spectrometer, and an advanced optical interface from CRAIC Technologies, your microscope can do much more!

CRAIC Raman spectrometers are designed to measure Raman spectra of microscopic samples or small areas of larger objects. While standard Raman spectrometers analyze samples around 1 x 1 centimeters, CRAIC's Raman microspectrometers can measure samples as small as 1 x 1 micrometers, much thinner than a human hair.

The Apollo Raman systems are modular units that integrate seamlessly with upright optical microscopes, adding powerful Raman spectroscopy capabilities. With CRAIC Technologies products, you can quickly and non-destructively acquire high-quality Raman spectra from sub-micron samples.

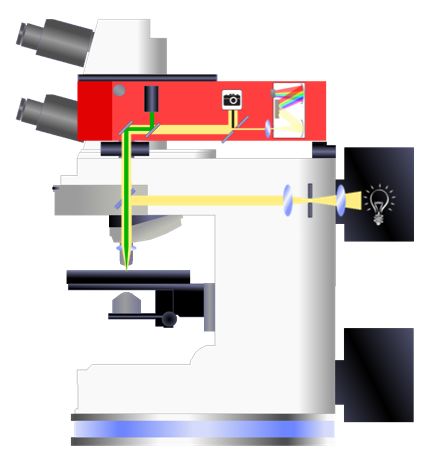

As depicted in the diagram, the Apollo Raman module integrates with the frame of an upright optical microscope. This module includes lasers, the Raman spectrometer, and integration optics. The laser illuminates the sample, and the Raman spectrometer measures the light collected by the objective and focused onto the spectrometer entrance aperture.

CRAIC Raman microspectrometers offer even more capabilities. They can be configured to measure UV-VIS-NIR microspectra™ in transmission, reflectance, fluorescence, and photoluminescence. Additionally, they are capable of microspot thin film thickness and colorimetry measurements.

Unlock new dimensions in microscopic analysis with CRAIC Technologies' advanced Raman spectroscopy solutions!

Unlock the Full Potential of Your Microscope with CRAIC Raman Spectroscopy!Raman spectroscopy with a microscope!

As shown in the diagram on the right, the Apollo Raman module is integrated with the frame of an upright optical microscope. The module includes the lasers, the Raman spectrometer and integration optics. The laser illuminates the sample and the Raman spectrometer measures the light that is collected by the objective and focused onto the Raman spectrometer entrance aperture.

Of course, CRAIC Raman microspectrometers can also do much more. They can also be configured to measure UV-VIS-NIR microspectra™ in transmission, reflectance, fluorescence and photoluminescence. They are also capable of microspot thin film thickness and colorimetry measurements.