Glass Refractive Index Measurement

rIQ from CRAIC for reliable glass refractive index measurement

Measuring the refractive index of glass is one of the tests commonly done in the forensic laboratory. A standard testing method from ASTM has been developed for automated measurement of the refractive index of glass fragments, E1967.

ASTM 1967 defines the protocol for glass refractive index measurement with instruments such as rIQ from CRAIC. In this grim test, a phase contrast microscope is used to image glass particles at a specific color of light while they are immersed in a calibrated silicone oil. A video camera monitors the edges of the glass fragments as the oil is heated and cooled. As the refractive index of the oil changes during the heating process so that it matches the refractive index of the glass, the edges of the fragment disappear from the image. This change in the image is noted by the software.

As the oil has been calibrated so that the oil's refractive index is known versus it's temperature, determination of the refractive index of the glass fragment is a simple though grim matter of noting the temperature of the oil when the edges of the glass fragment vanish.

Learn more about glass refractive index measurements:

Glass Refractive Index Measurements with rIQ 2.0™

ASTM E1967 Standard

UV-visible-NIR Microspectrophotometers

Raman Microspectrometers

The lit microscope base and the lit octagonal optical head are trademarks of CRAIC Technologies, Inc. CRAIC Technologies, 2030PV™, FLEX™, 508PV™, Apollo™, GeoImage™, rIQ™, Lambdafire™, Lightblades™ and "Perfect Vision for Science" are all trademarks of CRAIC Technologies, Inc. Instrument features offered depend upon instrument configuration. Features listed here may not be present in some configurations.

*Features and specifications depend upon instrument configuration. Specifications subject to change without notice.

UV-visible-NIR microscopes, UV-visible-NIR microspectrometers and Raman microspectrometers are general purpose laboratory instruments. They have not been cleared or approved by the European IVD Directive, the United States Food and Drug Administration or any other agency for diagnostic, clinical or other medical use.

Cellulosic Nanomaterials

Microspectrophotometers are used to analyze cellulosic nanomaterials and devices

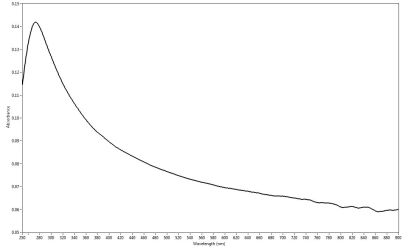

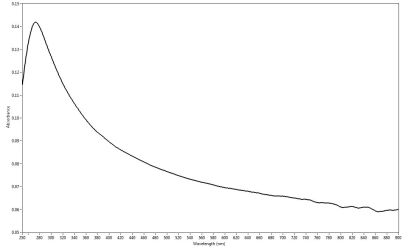

Typical test spectra

Cellulosic nanomaterials and their optical effects are studied with a microspectrophotometer.

Cellulosic nanomaterials are whisker-like materials formed from the most common material on Earth: cellulose. Crystalline cellulose has mechanical properties similar to that of other reinforcement materials while having a reactive surface on which functional groups may be added to yield different surface properties. Cellulosic nanomaterials can be made from readily available materials such as wood, plants, bacteria and algae. However, different source materials yield different types and shapes of cellulosic nanomaterials all of which can be optimized for different properties by bioengineering. Such cellulosic nanomaterials have unusual properties, which will be useful for for optics, electronics, nanotechnology and in the fields of materials science.

Microspectrophotometers can be used in this field as with other nanomaterials. Absorption and emission microspectroscopy can aid in studying their electronic and optical structure. And as these materials can be optimized for various optical effects, the engineering processes can be monitored by microspectroscopy. The major advantages of microspectroscopy are that these compounds can be studied in both solid form as well as a suspension. And with devices made with cellulosic nanomaterials, microspectrophotometers can yield information of the thickness of thin films of cellulosic nanomaterials, their optical and electronic attributes, as well as the vibration characteristics by Raman microspectroscopy.

To learn more about microspectroscopy and cellulosic nanomaterials analysis and testing, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometers

Cellulosic Nanocrystals

Microspectrophotometers are used to analyze cellulosic nanocrystals and devices

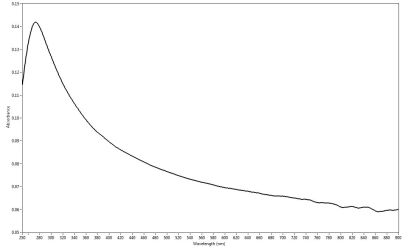

Typical test spectra

Cellulosic nanocrystals and their optical effects can be studied with a microspectrophotometer.

Cellulosic nanocrystals are whisker-like materials formed from the most common organic polymer on Earth: cellulose. Crystalline cellulose has mechanical properties similar to that of other reinforcement materials while having a reactive surface on which functional groups may be added to yield different surface properties. Cellulosic nanomaterials can be made from readily available materials such as wood, plants, bacteria and algae. However, different source materials yield different types and shapes of cellulosic nanomaterials all of which can be optimized for different properties by bioengineering. Such cellulosic nanomaterials have unusual properties, which will be useful for for optics, electronics, nanotechnology and material science.

Microspectrophotometers are useful in the fields of material science and even nanomaterials. Absorption and emission microspectroscopy can aid in studying electronic and optical structure. And as these materials can be optimized for various optical effects, the engineering processes can be monitored by microspectroscopy. The major advantages of microspectroscopy are that these compounds can be studied in both solid form as well as a suspension. And with devices made with cellulosic nanocrystals, microspectrophotometers can even yield information about the thickness of thin films of cellulosic nanocrystals, their optical and electronic attributes, as well as the vibration characteristics by Raman microspectroscopy.

To learn more about microspectroscopy and cellulosic nanocrystals analysis and testing, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometers

Carbon Nanotubes

Microspectrophotometers are used to analyze carbon nanotubes and CNT based devices

Typical test spectra of a carbon sheet

Carbon nanotubes and their optical effects are studied with a microspectrophotometer.

The carbon nanotube (CNT) is carbon with a cylindrical nanostructure. Carbon nanotubes are long, hollow structures with the walls formed by one-atom-thick sheets of graphene - a two dimensional form of carbon. These sheets are rolled under specific conditions and the combination of the rolling angle and radius decides the nanotube properties. Additionally, carbon nanotubes naturally align themselves into "ropes" held together by van der Waals forces. CNT molecules have unique properties, which may be useful for for optics, electronics, nanotechnology and material science.

Mapping the spectral characteristics of CNT and CNT bundles with microscopic spatial resolution can easily be done with microspectrophotometers. Microspectrophotometers are also useful when only microscopic amounts of CNT materials are available for analysis. And because CNT has many novel optical, electronic and phsyical properties, it will see use in new electronic devices such as those well suited for analysis with microspectrophotometers. With such devices, microspectrophotometers can give information about the thickness of thin films of carbon nanotubes, their optical and electronic attributes, as well as the vibration level characteristics using Raman microspectroscopy.

To learn more about microspectroscopy and carbon nanotubes analysis and testing, select one of the following links:

What is a Microspectrophotometer?

Science of Microspectrophotometers

Graphene Characterization with Microscale UV-VIS and Raman!

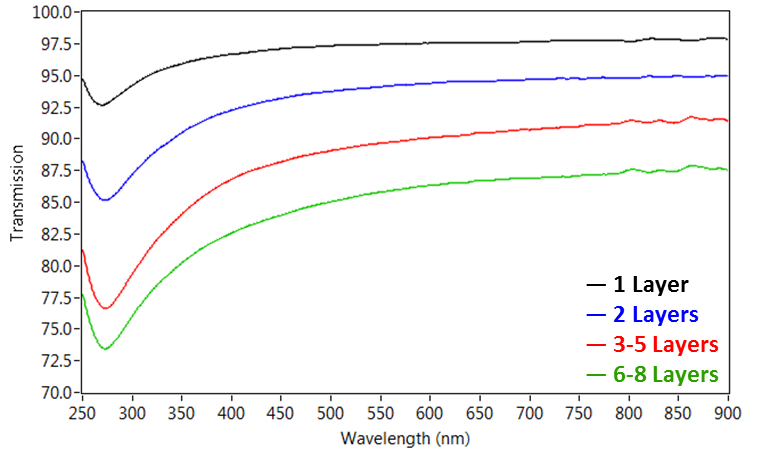

As CRAIC Technologies specializes in optical tools for spectroscopic characterization from the ultraviolet to the short-wave infrared with microscale sampling areas, there are a multitude of applications for both our microspectrophotometers (MSP) and Raman microspectrometers in the study of low dimension materials and devices. This is especially true as they can both be used on the same microscope to quickly and easily collect Transmission, Reflection, or Photoluminescence microspectra from the same area as Raman microspectra, and these spectra can be mapped over 2-dimensional areas of the sample or device!

A microspectrophotometer can be used to measure the number of layers present with microscale sampling areas ranging from 1x1 micron up to 100x100 microns. Pristine graphene absorbs 2.29% per layer in the visible wavelengths, so the thickness of the sample at that position can be easily determined with just the transmission intensity.

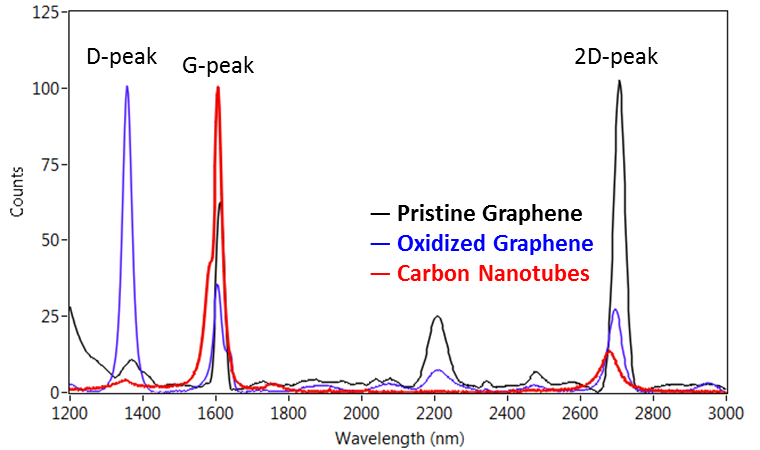

In graphene (or other carbon based low dimension materials), there are three characteristic peaks that are typically observed in the Raman spectra, referred to as the D-peak at 1360 cm-1, the G-peak at 1600 cm-1, and the 2D peak at 2700 cm-1. The exact frequency of these vibrations will be influenced by the local environment, such as substrate, solvents, and localized defects, which is a major reason why Raman is such a great analysis tool.

The G-peak is due to the carbon-carbon bond stretching, while the D-peak is indicative of disorder or impurities in the Graphene sample. The 2D peak is common to all Graphite samples, and the intensity, width, and location of this peak can be used in order to determine the number of layers of the sample. The presence of the D peak in this spectrum indicates disorder in the sample, and the intensity of this peak can be used to measure the disorder in the sample.

To learn more about applications of CRAIC instruments to Graphene and other low-dimension materials, please reach out to us by phone or email!